Fasteners play a crucial role in our daily lives by ensuring the stability of structures and components that hold objects such as automobiles, bridges, and appliances together. They are the unsung heroes of every mechanical part, from construction to manufacturing, providing reliable and secure operation. Fasteners may appear as simple devices, but they consist of complex attributes that determine their quality and integrity. To ensure that fasteners meet basic standards and specifications, they undergo testing and quality control before being put into commercial use. These processes are crucial steps in making the right choice of durable and high-quality fasteners for various industries.

Significance of Fastener Quality Control

Safety Assurance

Safety is the paramount consideration for applications requiring complex and reliable fastener installations, such as in automobiles, aerospace, and construction. A single fastener failure can lead to catastrophic accidents, jeopardizing the safety of consumers and many others. This is why quality control measures are indispensable and should be regulated by manufacturers. Rigorous testing protocols help identify and eliminate substandard fasteners, reducing the risk of structural failures and accidents in various fields.

Compliance with Standards

Fastener quality control includes compliance with industry and regulatory standards. Different industries have specific requirements for fasteners, such as strength, corrosion resistance, and durability. By implementing and adhering to these standards, manufacturers can ensure that their equipment and tools meet the necessary specifications for various industries, ensuring they are fit for their intended purposes.

Types of Fastener Testing

Mechanical Testing

Mechanical testing involves subjecting fasteners to various forces to evaluate their strength and performance characteristics. Testing includes various types, typically encompassing tension, shear, and fatigue testing. Tension testing measures the maximum load a fastener can withstand before breaking, while shear testing assesses its resistance to lateral forces. Fatigue testing simulates the repeated stresses that fasteners may experience over time, ensuring they can withstand long-term use without failure.

Material Analysis

This testing method involves examining the composition of fastener materials to verify their suitability for specific applications. Material analysis includes testing factors like material hardness, chemical composition, and microstructure. Understanding these properties is crucial to ensure that fasteners can withstand environmental conditions and mechanical stress.

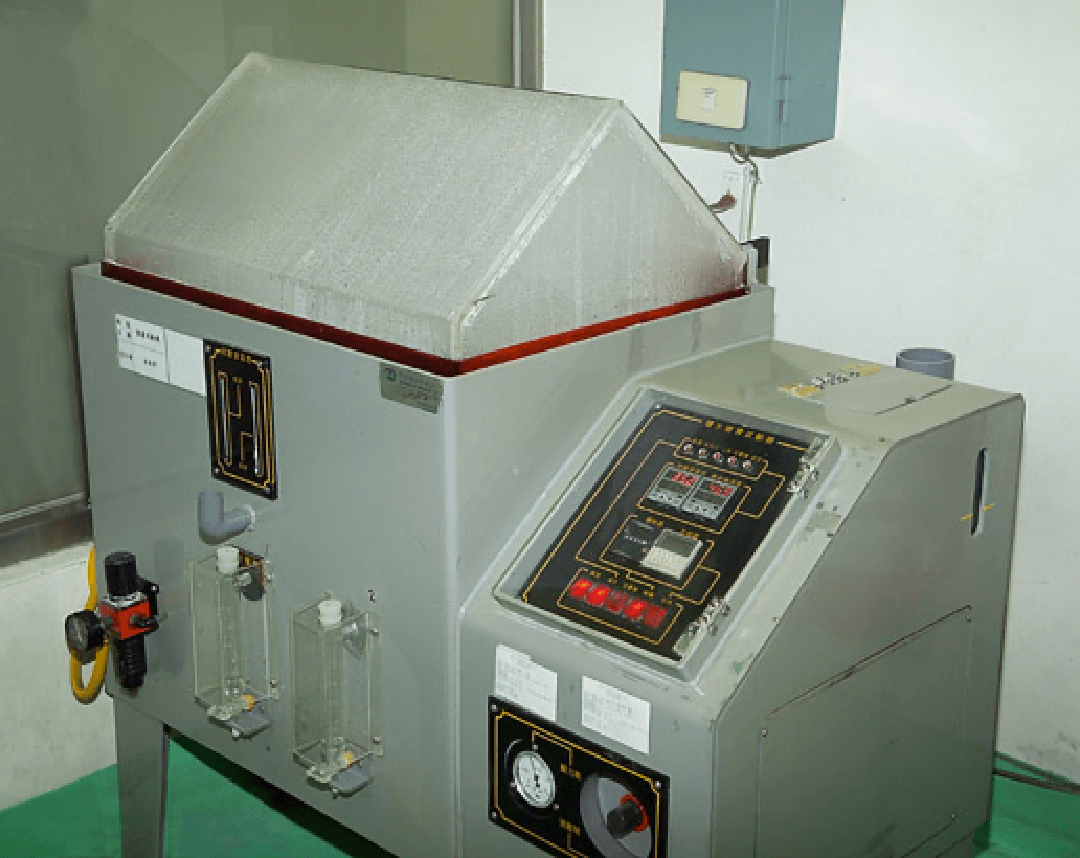

Corrosion Testing

Corrosion is a common threat to fasteners, especially in outdoor environments where corrosive elements are present. Corrosion testing evaluates a fastener's rust resistance and other forms of corrosion resistance. Various methods, such as salt spray testing and exposure to corrosive chemicals, simulate corrosion conditions and measure the durability of fasteners.

Dimensional Inspection

The accuracy of fastener dimensions or sizes is critical for their installation and normal operation in applications. Dimensional inspection ensures that fasteners meet specified size and shape requirements, including measurements of pitch, diameter, length, and critical dimensions.

Non-Destructive Testing (NDT)

Non-destructive testing methods, such as ultrasonic testing, magnetic particle inspection, and radiographic inspection, evaluate the integrity of fasteners without causing damage. These techniques are particularly useful for assessing hidden or internal defects that could compromise fastener performance.

Production Quality Control

Implementing effective quality control measures during the fastener manufacturing process is a key factor affecting their integrity and durability in applications. These strategies include process monitoring, statistical process control, and the use of advanced technologies like automated inspection systems. Quality control personnel work closely with production teams to help identify and rectify issues as they arise, ensuring that only high-quality fasteners enter the market and are distributed across multiple industries.