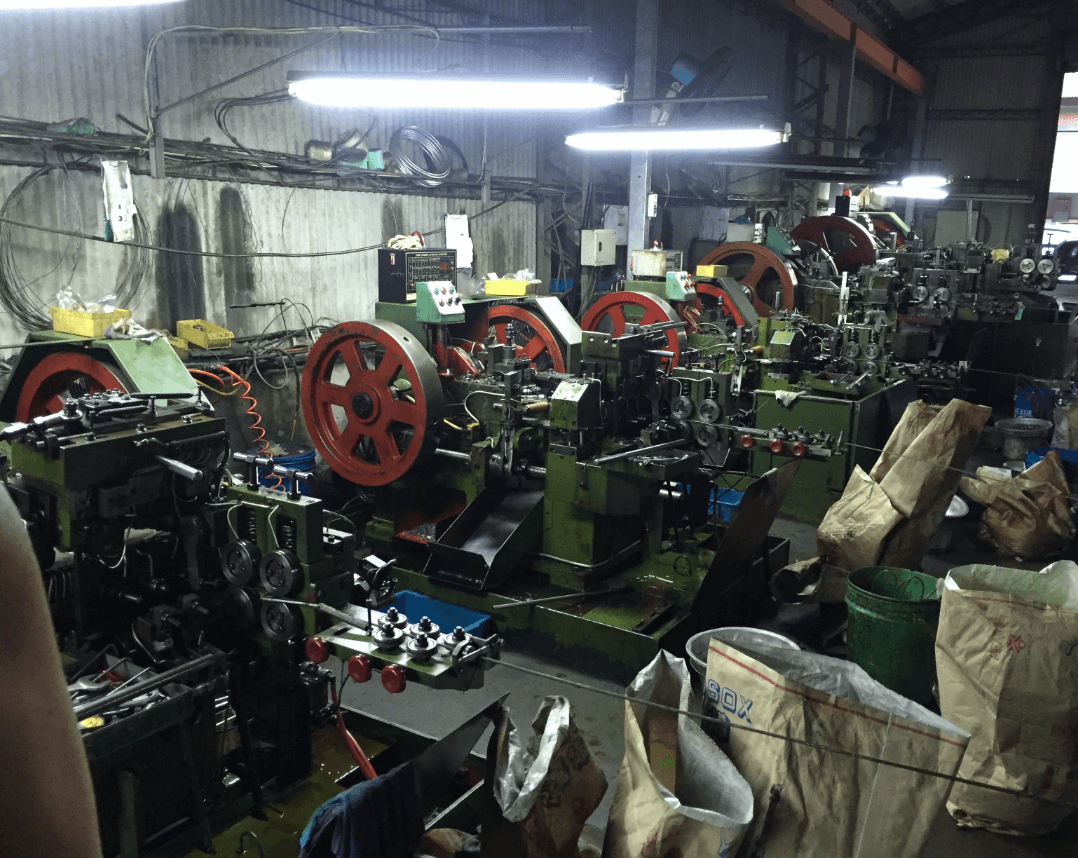

The fasteners industry plays a crucial role in various aspects of our lives, even if it's not always in the spotlight. For most major industries involving structures, machinery, equipment, and components, fasteners are essential for their operations. Though fasteners may seem small and simple, they serve as critical tools that connect our world, providing safety for many structures and products.

In recent years, the global fastener supply chain has encountered several challenges, including economic disruptions, the COVID-19 pandemic, technological advancements, and complex fastening requirements. Nonetheless, it has shown remarkable resilience in adapting to adversity and has become stronger than ever. Various complex factors affecting the fastener industry have contributed to supply chain stability challenges, such as economic fluctuations, trade tensions, the COVID-19 pandemic, and material shortages.

Adaptive Actions in the Fastener Supply Chain

Despite challenges, the fastener supply chain's exceptional resilience has provided promising prospects in many ways. Here are key factors influencing its adaptability throughout the odds:

Diversification: Fastener manufacturers diversify product supply and customer bases to reduce dependence on specific industries, making them less vulnerable to market fluctuations. This step provides companies with more choices and the potential to offer different types of equipment and components in various sectors.

Global Sourcing: Many companies adopt global sourcing strategies, ensuring access to numerous suppliers and distributors worldwide, and minimizing the impact of regional disruptions on fastener demands.

Technological Integration: Most suppliers employ automation and digitalization to enhance service efficiency and reduce dependency on labor. This ensures smoother operations around the company, even amid labor shortages.

Collaboration and Communication: Strengthening collaboration and communication with suppliers and customers helps in more agile responses to challenges.

Inventory Management: Implementing advanced inventory management systems enables companies to swiftly adapt to changing demands and supply dynamics.

Effective Strategies for Fastener Supply Chains

The fastener supply chain continuously provides optimal solutions, leaving valuable lessons for other industries. Here are some effective methods to sustain the growth of fastener supply chains:

- Adaptability: Diversify product lines, customer bases, and supply sources to reduce vulnerability to external impacts.

- Embrace Technology: Combine automation, data analytics, and digital tools to enhance operational efficiency and flexibility.

- Supply Chain Visibility: Invest in systems providing real-time visibility into the supply chain to respond rapidly to disruptions.

- Collaboration is Key: Establish robust partnerships with suppliers and customers, building a flexible ecosystem to jointly tackle challenges.

- Risk Mitigation: Develop risk mitigation strategies considering economic fluctuations, trade tensions, and global events.