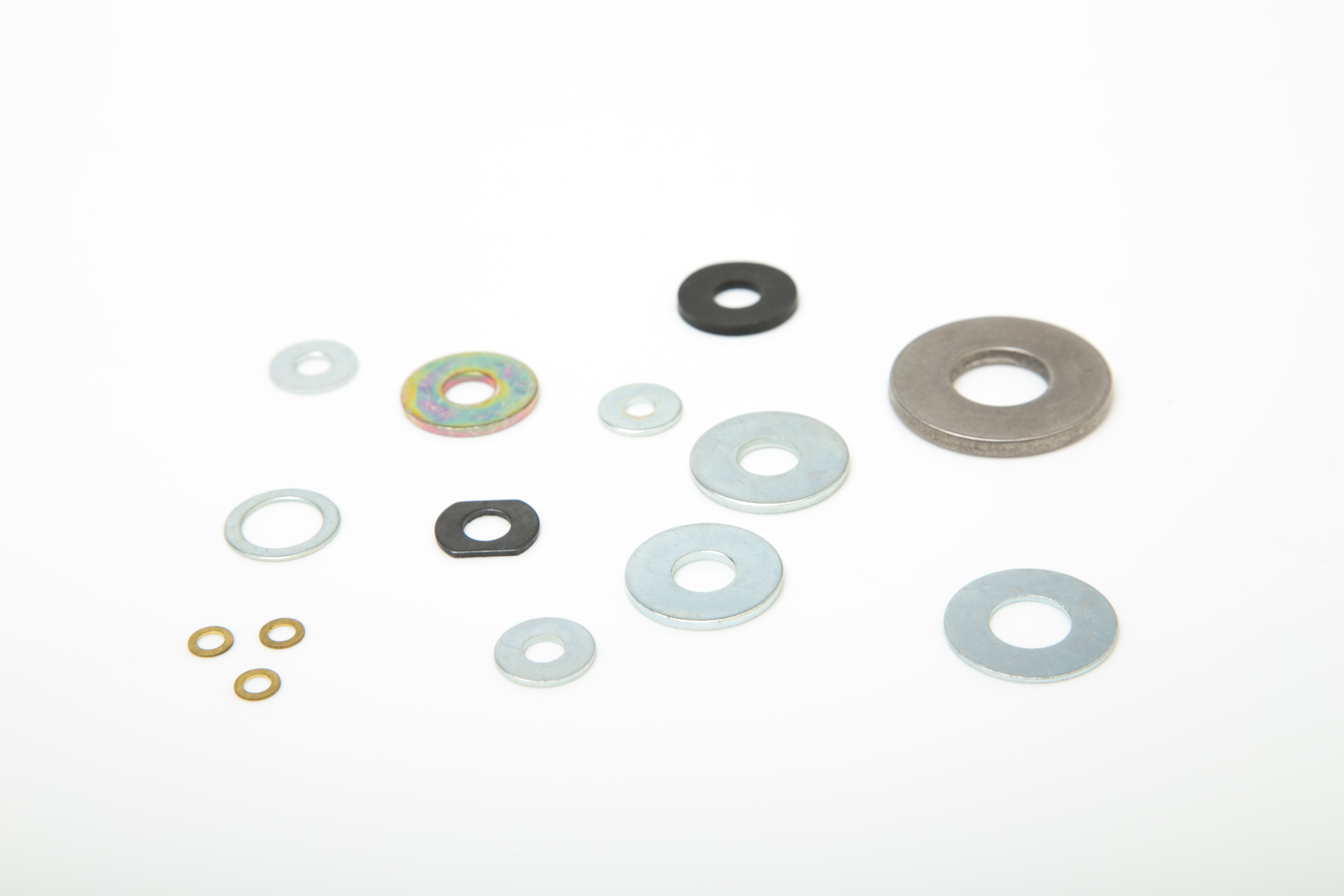

Washers

often overlooked in large industries like construction and manufacturing, are flat, usually circular discs made of various materials, including metal, plastic, or rubber. These seemingly simple components play a crucial role in ensuring structural integrity and stability. While easily underestimated, washers contribute significantly to enhancing the efficiency and reliability of fastening connections. Here are the primary functions of these fastening washers:

Load Distribution: One of the primary functions of washers in fastening is to distribute the load applied by fasteners onto a larger surface area. This helps prevent damage, such as preventing fasteners from piercing the material they are securing, thus weakening the connection.

Damage Prevention: Washers act as protective barriers between surfaces and fasteners, reducing the risk of friction and damage. This is particularly important when connecting materials susceptible to damage or deformation.

Locking and Sealing: Specialized washers, such as locking washers and sealing washers, provide additional benefits in applications. Locking washers prevent loosening due to continuous vibrations or movement, while sealing washers create watertight or airtight seals, commonly used in piping.

Factors Affecting Washer Efficiency:

Material Selection: Like other fasteners, the type of material used for washers significantly impacts their efficiency. Common materials for washers include stainless steel, brass, and nylon. Stainless steel washers are popular due to their corrosion resistance, while nylon washers are used in applications involving electrical insulation.

Size and Shape: Washers must be appropriately sized and shaped to match the fastener and application. Properly sized washers ensure load distribution and fastening stability. For instance, flat washers are suitable for general applications, while spring washers are used when preventing loosening is necessary.

Surface Treatment: The quality of surface treatment on washers also affects their efficiency. A smooth surface treatment reduces friction, ensuring even load distribution. Rough or uneven washer surfaces might lead to stress concentration, weakening the connection.

Application Conditions: Considering environmental conditions during fastening applications is crucial. Several conditions in the environment need special consideration when selecting washers. For instance, harsh environmental conditions like exposure to chemicals, extreme temperatures, or high humidity may require specific washers to ensure long-term reliability.

Torque: The efficiency of washers might be affected if the fasteners are not properly torqued or excessively tightened. Insufficient torque might lead to the gradual loosening of components while over-tightening could damage washers, other related fasteners, and the secured material.